Call: 07971405770

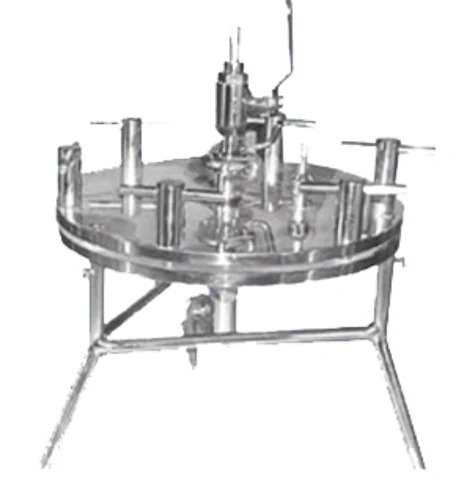

5000L Pressure Nutsche Filters

Price 1750000 INR/ Piece

MOQ : 1 Piece

5000L Pressure Nutsche Filters Specification

- Usage & Applications

- Chemical Industry

- Features

- Corrosion Resistance

- Material

- Stainless Steel

- Capacity

- Upto 5000 Ltr

- Control Mode

- Automatic

- Color

- Silver

- Warranty

- 1 Year

5000L Pressure Nutsche Filters Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 5-7 Days

- Main Domestic Market

- All India

About 5000L Pressure Nutsche Filters

Discover the unparalleled performance of the 5000L Pressure Nutsche Filters, a cost-effective solution designed for the chemical industry. Manufactured using excellent-grade stainless steel, this corrosion-resistant filter features automatic control for precision operations and exceptional reliability. With a silver finish and soaring capacity of up to 5000 liters, these filters redefine operational efficiency. Backed by a 1-year warranty, it ensures peace of mind while delivering unprecedented results. Whether youre exporting, manufacturing, or trading, this top-tier equipment is perfect for your needs. Get it now and elevate your processing game! Application Overview: The 5000L Pressure Nutsche Filter is ideal for application media like chemical slurry and filtration processes requiring precision under pressure. Its automatic controls ensure easy direction of use and flawless handling. Competitive advantages include superior corrosion resistance and long-term reliability, making it a game-changer for businesses aiming for efficient and effective chemical filtration operations. Supply & Packaging Details: The 5000L Pressure Nutsche Filter is delivered with care, ensuring excellent shipment and safe packaging practices. Each unit is securely packaged to avoid transit damage and maintain product integrity. For sample policy flexibility, reach out for further assistance and details. Designed for timely delivery and seamless transactions, this product guarantees reliability from procurement to operational implementation.

FAQs of 5000L Pressure Nutsche Filters:

Q: How is this product beneficial for chemical industries?

A: The 5000L Pressure Nutsche Filter enhances filtration processes by providing automated operation, corrosion resistance, and large capacity, ensuring efficiency and reliability.Q: What makes the material ideal for industrial applications?

A: Stainless steel is durable, offers corrosion resistance, and remains unaffected by harsh chemicals, offering excellent performance in demanding environments.Q: When should maintenance be performed on this equipment?

A: Regular maintenance should be performed as per the manufacturers guidelines or annually to ensure optimal functionality.Q: Where can the equipment be used apart from the chemical industry?

A: It may also be used in pharmaceutical plants or other industries requiring precise filtration and moisture removal.Q: What is the process for handling this product?

A: The automatic control mode simplifies handling, ensuring user-friendly operation with minimal intervention for efficient filtration.Q: How can this product improve operational cost management?

A: Its robust design minimizes downtimes, while the corrosion-resistant material reduces replacement needs, making it a cost-effective solution.Q: What specific usage does this product excel in?

A: It excels in high-capacity filtration processes requiring precision and operational accuracy under pressure.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Nutsche Filter Category

20000L Pressure Nutsche Filters

Price 175000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Capacity : >20000 Ltr

Features : Corrosion Resistance

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese